What are the API Procedures for Testing the Viscosity of Mud?

The API mud test is commonly used to evaluate the rheological properties of drilling fluids (often called “mud”) (how the mud flows and performs while moving). The procedures for measuring funnel viscosity, plastic viscosity, yield point, and gel strengths are standardized in the API RP 13B-1 (Recommended Practice for Drilling Fluids Sampling and Testing) guidelines.

Funnel Viscosity (also known as Marsh Funnel Viscosity)

This test measures the time it takes for a specific volume of mud to flow through a funnel, which can provide an indication of the fluid’s flow properties.

Procedure:

- Prepare the Mud Sample: Ensure the mud is at the appropriate temperature, typically at room temperature or the temperature under which the test is to be conducted.

- Clean the Funnel: Clean the Marsh Funnel and ensure it is free of contaminants.

- Fill the Funnel: Slowly pour the mud into the Marsh Funnel until the liquid reaches the top mark, making sure there are no air pockets.

- Measure the Flow Time: Release the mud by opening the valve (or removing ones finger) from preventing flow at the bottom of the funnel and immediately start a stopwatch. Measure the time it takes for the mud to flow out of the funnel and pass through the outlet. The flow should be measured in seconds for the mud to reach the 1 quart level mark (or the 1 liter for metric measurements) of mud.

- Record the Time: The time measured is typically reported in seconds, and the unit used is seconds per quart (sec/qt) or seconds per Liter (sec/L).

Plastic Viscosity (PV)

Plastic viscosity is a measurement of the internal friction between the micro-fine particles in the mud when it is flowing. It is a measure of the size, shape, and number of colloidal particles and it is typically measured in the mud industry using a rotational viscometer. In general, a higher ultra fine content such as barite or reground micro-fine cuttings results in a higher plastic viscosity. The plastic viscosity can be reduced by minimizing the ultra-fine solid content through centrifuging or dilution.

PV is reported in units of either centipoise (cP) or millipascal second (mPa·s).

Procedure:

- Prepare the Mud Sample: Ensure the mud is homogeneous and strain through a sieve to ensure it is free of cuttings or lumps of poorly hydrated additives.

- Record the mud temperature (preferably around 120°F or as required for the test).

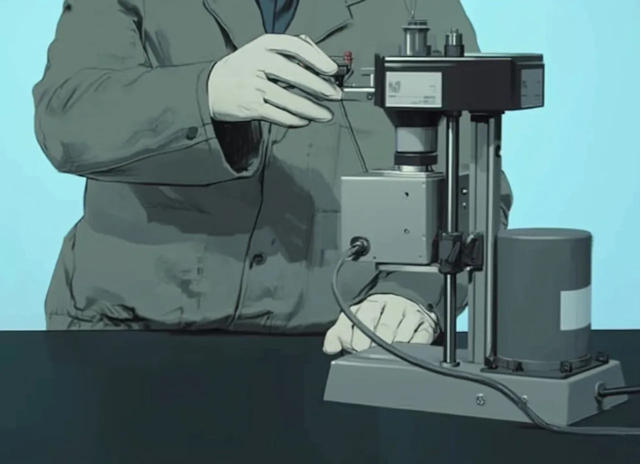

- Viscometer Setup: Use a rotational viscometer (such as a Baroid or Fann viscometer). Install the proper spindles (typically #1 or #2) and ensure it is calibrated.

- Measure the Readings: Rotate the viscometer and record the readings at different speeds, typically 600 rpm and 300 rpm. For more accurate results, measurements at 200 rpm, 100 rpm, and 6 rpm are also taken.

- Calculate Plastic Viscosity:

Plastic Viscosity (PV) (cP) = 600 rpm reading − 300 rpm reading. Since 1 cP = 1 mPa·s, the formula for PV is the same.

Yield Point (YP)

The Yield Point is a measure of the mud’s ability to resist flow at low shear rates (shear stress) and is an important indicator of mud stability. It is an indication of the chemical force of attraction between the constituent particles and is reported in lbf./100 ft2 or Pa

Calculate Yield Point:

Yield Point (YP) (lbf./100 ft2) = 300 rpm reading−Plastic Viscosity (PV)

Yield Point (YP) (Pa) = [300 rpm reading−Plastic Viscosity (PV)] ÷ 2

If the mud’s yield point is calculated as a negative number, it is typically reported as 0, indicating no measurable yield point at the given conditions. Pure water has a yield point of 0.

Gel Strengths (10-sec and 10-min Gel Strengths)

Gel strengths are used to assess the mud’s ability to form a gel after being at rest. They are important for understanding the mud’s behavior after circulation stops. Gel strengths are measured in units of either l b f / 100 f t 2 or Pa

Procedure:

- Prepare the Mud Sample: Ensure the sample is thoroughly mixed and free of clumps or air pockets.

- Fill the Viscometer: Use a rotational viscometer to measure gel strengths and shear the mud at 600 RPM

- Stop rotating: After mixing, allow the mud to rest for the required time, usually 10 seconds and 10 minutes.

- Record Gel Strengths: After the resting period: Set the viscometer to 3 rpm and record the gel strength at 10 seconds (this is the initial gel strength).

- After waiting for a further 10 minutes, record the 10 minute gel strength.

These readings are the maximum deflection on the viscometer at 3 rpm, reported in API units of lb/100 ft² (pounds per 100 square feet) or divining the maximum deflections by 2 to report in Pa. If the viscometer has no automatic 3 rpm setting, the tester must turn the viscometer at an estimated 3 rpm by hand to obtain the gel strengths. Since no two testers will turn at exactly the same constant speed, slight inconsistencies in gel strength readings may occur between different testers.

The 10-sec Gel Strength reflects the mud’s ability to form a gel shortly after circulation stops, while the 10-min Gel Strength measures the mud’s ability to maintain structure over time.

Summary of Key Measurements

API Units:

1. Funnel Viscosity (s/qt): Flow time of 1 quart of mud (seconds per quart).

2. Plastic Viscosity (PV) (cP): Difference between the 600 rpm and 300 rpm viscometer readings.

3. Yield Point (YP) (lbf/100 sq ft): Difference between the 300 rpm reading and plastic viscosity.

4. Gel Strengths (lbf/100 sq ft): 10-second and 10-minute gel strengths measured in lb/100 ft².

SI Metric Units:

1. Funnel Viscosity (s/L): Flow time of 1 liter of mud (seconds per liter).

2. Plastic Viscosity (PV) (mPa·s): Difference between the 600 rpm and 300 rpm viscometer readings.

3. Yield Point (YP) (Pa): Difference between the 300 rpm reading and plastic viscosity.

4. Gel Strengths (Pa): 10-second and 10-minute gel strengths measured in lb/100 ft².

For more information on Drilling Mud for Well Control, read my Well Control Manual, which may be purchased in the Catalogue section of this website at: Well Control Manual V2.6 by Edwin Ritchie