Trip Tank: Essential for Accurate Measurement During Well Operations

A

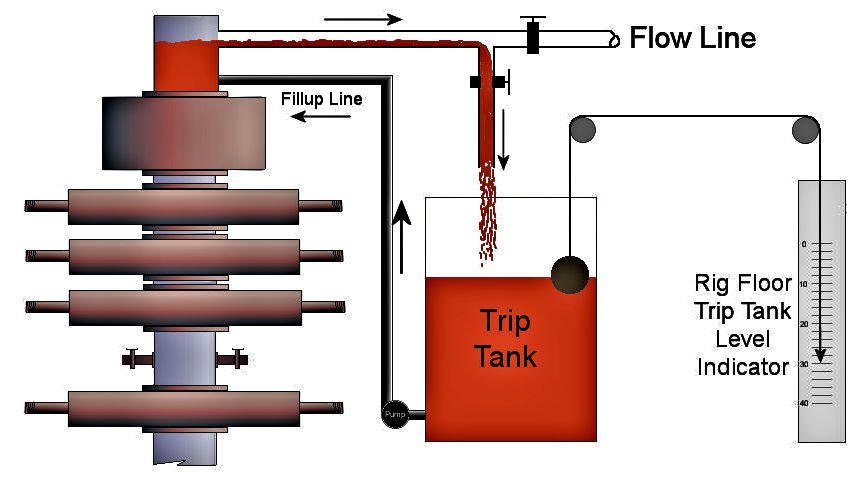

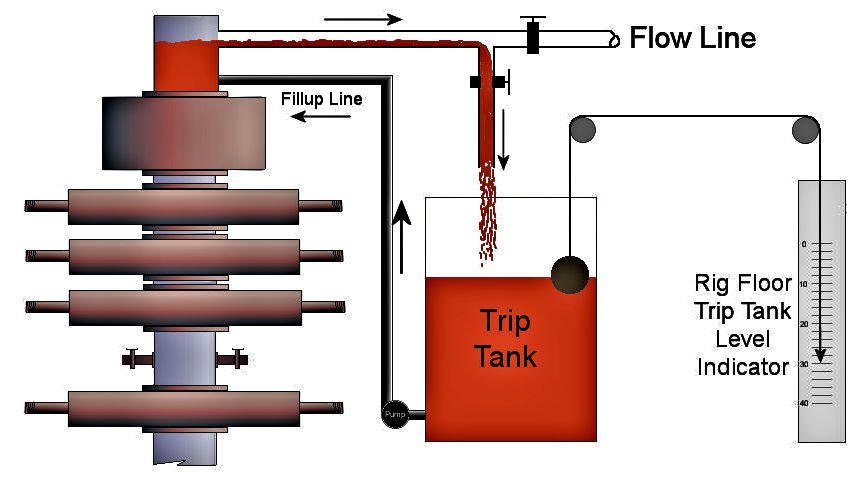

trip tank plays a crucial role in ensuring accurate measurement of fluid returns during trips or periods of non-circulation. Without it, the driller might struggle to detect small differences between the anticipated and the actual returns, especially in a large active system. For instance, in a typical 700-barrel tank, a mere one-inch gain could equal approximately 7.5 barrels of fluid.

In the past, drillers had to count the number of pump strokes required to fill the hole at regular intervals. This method, however, was prone to inaccuracies due to potential errors in estimating pump efficiency. Today, the trip tank, equipped with a 3” to 4” centrifugal circulating pump, is the standard method for measuring hole fill during trips and non-circulation periods, significantly reducing the likelihood of serious incidents.

How the Trip Tank Works

To measure and monitor fluid returns, the driller diverts them into a smaller, auxiliary tank known as a

trip tank. For example, in a typical 40-barrel trip tank, each inch on the gauge might represent just 0.4 barrels of fluid. This smaller volume allows for more precise monitoring compared to larger, active systems.

Trip tanks are often standalone units, equipped with an internal gauge marked off in one-barrel intervals or even smaller increments. The volume of a trip tank can vary, typically ranging from 10 barrels to 100 barrels, depending on the size of the rig. Smaller workover and completion rigs may use trip tanks as small as 5 barrels. It’s important that the trip tank has a larger capacity than the pill (slug) tank. On smaller rigs, the trip tank may even be a separate compartment built into the mud tank.

Stripping Tanks: For Even Finer Measurements

In some cases, rigs are also equipped with a

stripping tank, a smaller tank used for extremely fine measurements, down to as little as 0.02 barrels per inch. However, due to their limited capacity,

stripping tanks are generally not suitable for use as trip tanks.

Measurement Methods and Monitoring

Trip tanks can be equipped with various measurement systems, such as mechanical floats attached to pulleys, or more advanced options like electronic sensors, sonar, or infrared sensors. These tanks are not considered part of the active system during drilling operations and are bypassed when the well is being circulated.

Despite this, trip and stripping tanks can still be monitored while circulating mud into the well through the fill-up line. Mud returns are then sent back via a return line, usually off the flow line. Any changes in the mud volume in the hole are immediately reflected in the trip tank’s fluid level, ensuring real-time monitoring.

Keeping the Mud in Motion

To maintain consistency, some trip tanks are equipped with paddle agitators or jets that stir the mud when it’s not being circulated. This keeps the mud evenly mixed and helps avoid inconsistencies that could lead to inaccurate measurements.

In summary, the trip tank is an indispensable tool in modern drilling operations, providing accurate, real-time fluid measurement that helps prevent well control issues and ensures a safer, more efficient drilling process.